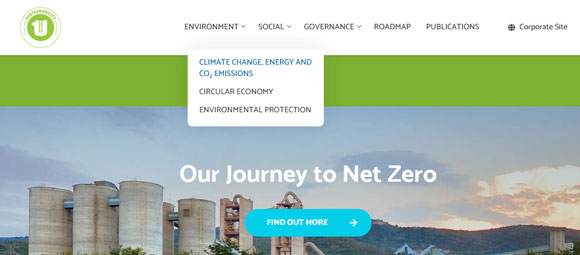

buzzi.com: the new Sustainability section

The renewed Sustainability section of the buzzi.com website has been released a few days ago: it is not a simple restyling of the existing pages, but a completely new browsing experience, which allows to delve deeper into the policies undertaken by the company for growth sustainable over time.

The section, connected to the other pages of the corporate website, offers a rich in-depth path, more modern in the user experience, which can also be undertaken starting from the address sustainability.buzzi.com

In addition to the 'environment', 'social' and 'governance' subsections, the presentation of the 'Our Journey to Net Zero' roadmap stands out: this story has been adapted for the context, for practical reading from any type of device.

Also worth mentioning is the new publications archive, to easily find all previous editions of the Sustainability Report.